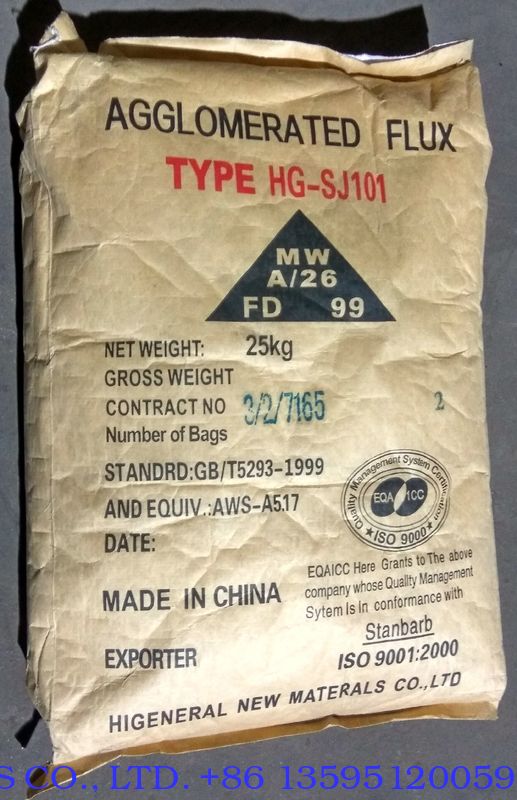

Agglomerated flux LH-HF101G

(for: Submerged Arc Welding Flux.)

Execute standards: GB/T 12740-2003 F48A4-H10Mn2A;

(Equal to the standards: AWSF7A4-EH14;F7A2-EM12K )

Description: Agglomerated Flux LH-HF101G is kind of special sintering flux withHighBasicity2.0,it is the grey spherical grain, Size of 10mesh to 60 mesh.The weld slag is easy to be removed on the welded position. The weldment has the high impact tenacity at low temperature.

Application: it is suitable for making the important steel structure, high strong steel structure, Chemical pressure vessel and nuclear vessel and various steel pipelinesuch as API pipeline type ofX60;X70 pipeline. It also can be used in multilayer welding, single-welding line with two sides, narrow gap SAW welding voluntarily. theLH-HF101Gflux shall need to combine with SAW wire(eg.: H10Mn2AH08MnMoA;;H08Mn2MoA, EH14,EA1,EA2).

3. Typical of flux composition range: ( chemical content % )

|

Item

Content

|

Si2O+TiO2

|

CaO+MgO

|

Al2O3+MnO

|

CaF2

|

S

|

P

|

| Tested results |

18 - 25 |

28 – 35 |

23 - 30 |

16 - 25 |

≤0.023 |

≤0.021 |

4. Typical mechanical properties: ( combination with welding wire type H10Mn2A ):

|

Combination

With welding wire type

|

YIED STRENGTH

σs (MPa)

|

Tensile strength

(σb)(Mpa)

|

Elongation

(δs)%

|

Impact Akv ( J )

(Below zero ℃)

|

| - 20℃ |

- 40℃ |

| H10Mn2A |

≥400 |

≥490 |

≥22 |

≥120 J |

≥102 |

| TESTED |

412 |

546 |

29 |

128 |

105 |

5. GUIDELINES FOR USAGE :

(1): Redry the flux for 2 hours at 300 –350 ℃ before use.

(2). completely remove rust, grease and moisture from the groove surface prior to welding.

Manufacturer: HIGENERAL NEW MATERIALS CO., LTD. &

LAIWU HULIN WELDING MATERIALS CO., LTD.

Chief Sales Representative: Martin Yang Cell: +86 13595120059

TEL/FAX: + 86 851 6745618 Tel: +86 6346032303

E-MAIL: weldingflux@163.com http:// www.higeneral.com

ADD.: THE NIUQUAN INDUSTRIAL PARK, LAIWU CITY, SHANDONG, CHINA.